Ultrasonic discharging.

Use ultrasound to proactively prevent problems such as bridging, ratholing and segregation.

Discharge aids for various applications

Thanks to unique technology with a wide range of application, your bulk solids process is optimally supported with ultrasound. Quiet, efficient and energy-saving.

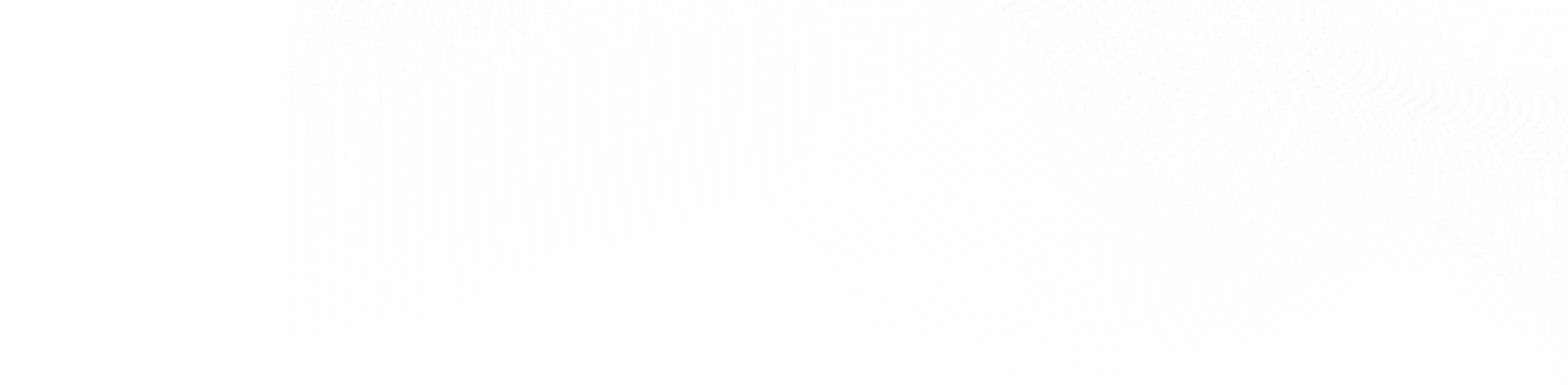

Silos

Hoppers

Spray towers

Mixing chambers

Chutes

Screw conveyors

Dosing units

Case studies

May we help you in finding a solution?

Get in contact with an ultrasonic specialist today.

Your advantages with our ultrasound at a glance

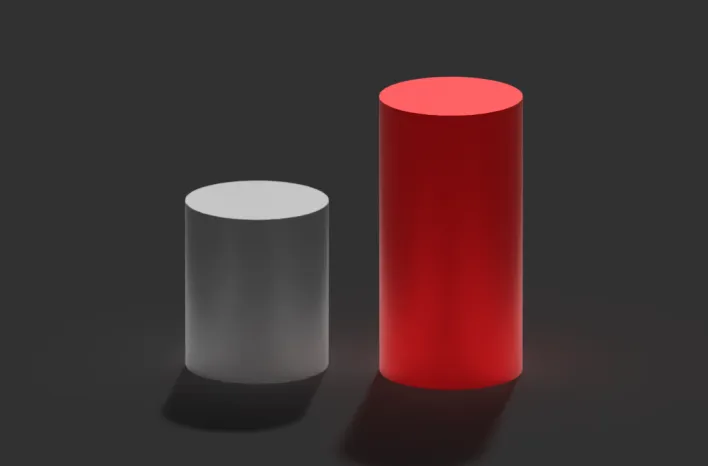

Ultrasound compared to mechanical and pneumatic flow aids

| Fulfillment level |  Artech Ultrasonic Artech Ultrasonic | Classical flow aids |

|---|---|---|

| Continuous flow | High | Medium |

| Complete residual emptying | High | Low-Medium |

| Throughput | High | Medium-High |

| Noise pollution | Low | Medium-High |

| Running costs | Low | Medium-High |

Why ultrasound is worth your investment

Whether as a retrofit or for your new plant or system, flowsonic® is the optimal addition.

The bulk material continuously in motion

Ultrasonic excitation minimizes static friction forces and allows bulk solids to flow more continuously and efficiently. Bulk solids problems such as bridging, ratholing and demixing are proactively prevented. Everything flowing smoothly = mass flow.

Increased overall plant effectiveness

The maximum productivity of your plant is put to the test by the use of ultrasound. Production output can be increased, in some cases considerably, by eliminating flow problems. At the same time, the quality is increased, as the buld solids handling equipment usually remains free of residual solids during product changes. Easy retrofitting possible.

Reduction of running operating costs - the silent way

In many cases, thanks to the barely audible ultrasound, human intervention such as hammer blows can be avoided. Employees are protected just as much as the environment. Thanks to low power and low energy consumption, ultrasound quickly becomes more affordable than noisy mechanical and pneumatic flow aids.

From metal powder to flour. Your industry is our industry

Additive Manufacturing

Whether powder preparation or powder recovery. With ultrasound, additive manufacturing reaches a new level of efficiency.

Battery

While improving the quality and consistency of the battery powder, ultrasound primarily helps to sieve and convey as much good grain as possible in the lowest micron range.

Chemical and Pharmaceutical

Whether for classification, homogenization, dust removal or for the purpose of smooth flow in bulk material handling equipment. In the chemical and pharmaceutical industries, ultrasound helps to optimize powder production.

Paints

Whether in the efficient production and processing of color powder or as a reliable partner for protective sieving in the powder coating process. Ultrasound helps to ensure the required color quality in an remarkably productive manner.

Food

In the food industry, ultrasound helps to optimize the flowability of bulk solids.

Further industries

Whether for classification of batterie powder with sieving machines or for residual cleaning of metal powder from cyclones. Regardless of the industry, Artech helps with ultrasound to achieve the optimal result.

May we help you in finding a solution?

Get in contact with an ultrasonic specialist today.